Table of Content

- 1 What Is A Steel Pipe And What Are Some Of Its Common Uses?

- 2 Unfolding the Basics of Steel Pipe

- 3 Diving Deeper into the Types of Steel Used in Pipes

- 4 A Closer Look at the Pipe Manufacturing Process

- 5 Evaluating the Standards of Steel Pipes

- 6 Key Considerations When Choosing Steel Pipes

- 7 How has the Evolution of Steel Pipe Technology Influenced Modern Infrastructure?

- 8 Frequently Asked Questions

- 8.1 What are the advantages of using steel pipe in construction projects?

- 8.2 How does the thickness and diameter of the steel pipe affect its strength and durability?

- 8.3 Are there any special considerations to keep in mind when working with steel pipe, such as safety precautions or maintenance requirements?

- 8.4 Can steel pipe be used in a variety of applications beyond construction?

- 9 Conclusion

What Is A Steel Pipe And What Are Some Of Its Common Uses?

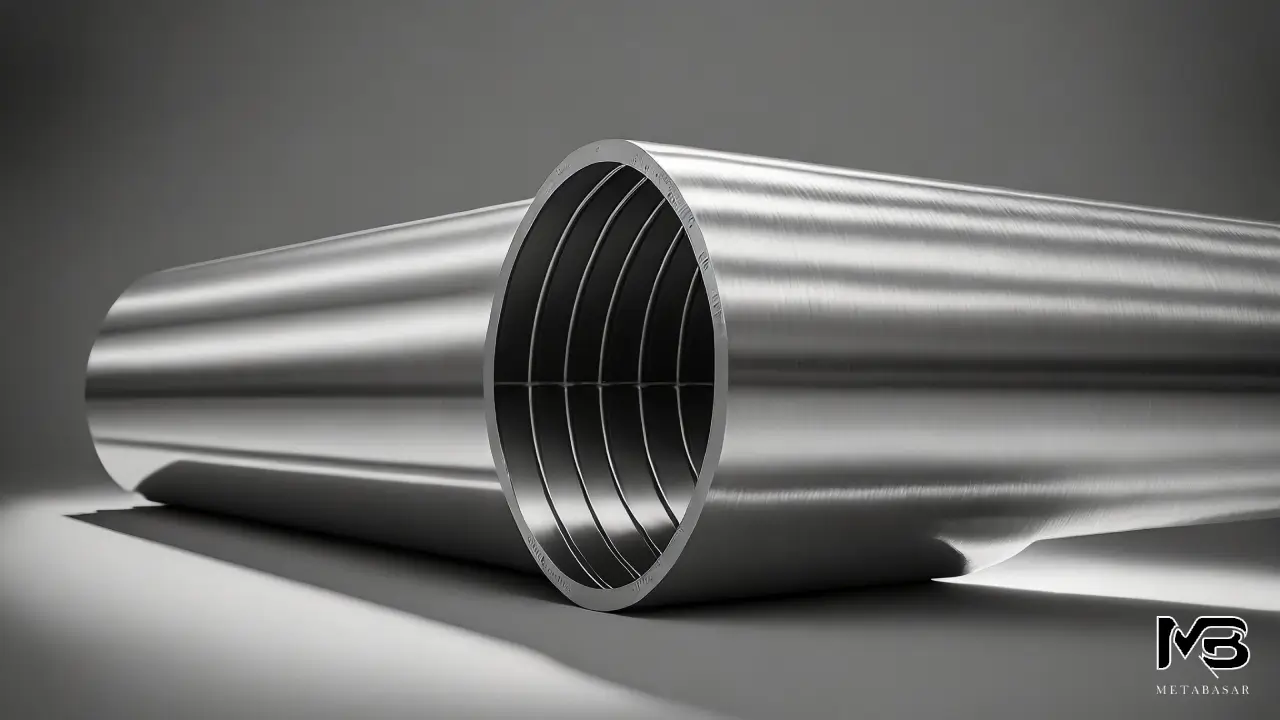

A steel pipe is a cylindrical hollow tube made of steel that is used for various purposes. It is commonly used in plumbing, construction, infrastructure projects, and transportation of fluids and gases. Steel pipes are also widely used in industries such as oil and gas, manufacturing, and agriculture.

Steel pipes are a staple in modern infrastructure, yet few people understand their true potential. These ubiquitous pipes can be found in everything from oil rigs to skyscrapers, and their versatility makes them a crucial component in countless industries.

In this blog, we’ll unlock the power of steel pipe by exploring its basic components, varied uses, and design parameters. We’ll also dive deeper into the types of steel used in pipes and investigate the manufacturing processes used to create them.

Additionally, we’ll evaluate the standards that govern steel pipe manufacturing and highlight key considerations when choosing steel pipes for your project. Lastly, we’ll explore how advancements in steel pipe technology have influenced modern infrastructure development. By the end of this post, you’ll have a newfound appreciation for the humble steel pipe and its role in shaping our world.

Unfolding the Basics of Steel Pipe

Advantages of steel pipe, including durability and strength, make it superior to other materials. Various types cater to different applications, while factors like size, thickness, and corrosion resistance play a crucial role in selection. The manufacturing process involves techniques such as hot rolling and welding, contributing to its resilience. Steel pipes find common use in construction, plumbing, and transportation.

Understanding What a Steel Pipe is

Steel pipes, serving as conduits for fluids and gases, are fabricated from steel plates. The welding seam of steel pipes ensures structural integrity, enabling diverse applications. This versatile manufacturing process allows for the production of pipes with varied specifications and mechanical properties, including wall thickness. Moreover, steel pipes are often coated to resist corrosion and are available in forms such as welded, seamless, and stainless steel.

Exploring the Varied Uses of Steel Pipe

Finding extensive utility across industries like construction, oil and gas, water distribution, and structural engineering, steel pipes play a crucial role in creating efficient drainage and sewage systems.

Their versatility enables usage in infrastructure, transportation, and manufacturing sectors, serving diverse fluid transportation needs from potable water to natural gas. Additionally, steel pipes are integral in developing modern, sustainable, and resilient structural frameworks, making them an essential component in various industrial applications.

Highlighting the Role of Design Parameters in Steel Pipe

In the manufacturing process, the integration of design parameters upholds industry standards, ensuring high-quality and durable solutions. Alloy composition and wall thickness directly influence steel pipe performance in various applications, while specifications such as diameter and coating are essential for meeting project requirements.

Understanding the impact of design on welding, corrosion, and mechanical properties is crucial, highlighting the need for seamless integration to optimize functioning in complex infrastructural systems.

Diving Deeper into the Types of Steel Used in Pipes

Delving into various steel types like stainless steel and alloy, crucial in pipe manufacturing, determines the mechanical properties, corrosion resistance, and wall thickness of the pipes.

Steel tubes are manufactured using different steel types, each with specific specifications and diameter, influencing the end application of the pipes. The choice of steel type plays a significant role in the performance and durability of the pipes, marking the end of the process.

Assessing the Different Types of Steel Pipes

Assessing the various types of steel pipes involves understanding their unique manufacturing processes and structural design. Seamless steel pipes, created from solid steel billets, boast exceptional strength with no welding seam. Alternatively, welded steel pipes are made by welding steel plate or coil, forming a visible weld seam.

Spiral steel pipes, produced by coiling steel plates, exhibit superior flexibility and durability due to their spiral design. Hollow section steel pipes feature a hollow structural section, ensuring robustness for specialized applications. Additionally, corrosion-resistant steel pipes, like stainless steel, offer unparalleled resilience in diverse industrial settings.

Exploring the Manufacturing Processes of Steel Pipes

The end of the process determines the mechanical properties of steel pipes, crucial for selecting the right pipe. Different processes, like welding and coating, yield pipes with distinct properties. Advanced technology is used to ensure high-quality products. Various techniques produce pipes of different specifications and sizes, contributing to the versatility of steel pipes.

A Closer Look at the Pipe Manufacturing Process

The manufacturing process of steel pipes involves utilizing various steel types, depending on the end application. Understanding this process is crucial for meeting specific industry standards and ensuring precise control of wall thickness and diameter.

It also allows for the production of steel pipes with the required mechanical properties and includes quality checks to guarantee product integrity. Assessing the end of the process ensures that steel pipes are tailored to meet diverse industry requirements.

Investigating the Mandrel Mill Process

Delving into the mandrel mill process reveals its vital role in creating seamless steel pipes of exceptional quality. This process utilizes a mandrel to craft hollow pipes with consistent diameter and wall thickness, ensuring superior mechanical properties and corrosion resistance.

It’s a critical technique for producing seamless steel pipes used across various applications, marking the end of the process. Such precision in manufacturing not only meets industry standards but also plays a significant role in modern infrastructure development.

Understanding the Electric Resistance Welding Process (ERW)

The end of the process involves the creation of welded steel pipes with high wall thickness precision, typically measured in cm. ERW process utilizes the application of pressure and electricity to weld steel pipes, ensuring seam integrity.

This process is commonly used to manufacture straight seam welded steel pipes in France. It results in welded steel pipes with consistent wall thickness and mechanical properties, made from materials like brass, copper, and acier.

Getting to Know the Electric Fusion Welding Process (EFW)

The end of the process involves the application of heat to fuse the steel plates, ensuring precise wall thickness control. EFW is often used for industrial and structural applications, producing welded steel pipes with excellent mechanical properties.

This method ensures the creation of welded steel pipes that meet stringent industry standards, making them suitable for various infrastructure and construction needs. The EFW process in France is vital for manufacturing large-diameter welded steel pipes.

Exploring the Submerged Arc Welding Process (SAW)

Employed for manufacturing welded steel pipes with thick wall thickness and high diameter, the submerged arc welding process involves submerging the arc beneath a flux layer, creating a strong weld seam in steel pipes.

This process yields welded steel pipes suitable for applications requiring robust mechanical properties and corrosion resistance, widely used for producing welded steel pipes for offshore and marine applications. SAW process ensures the creation of welded steel pipes with exceptional wall thickness and dimensional specifications.

Evaluating the Standards of Steel Pipes

Evaluating the adherence to industry standards is essential to ensure the quality and performance of steel pipes. This process involves thorough assessment of manufacturing processes, mechanical properties, and corrosion resistance.

Compliance with standards guarantees precision in wall thickness and diameter specifications, offering reliability and durability for specific applications. Understanding the significance of standards in steel pipe manufacturing is crucial for maintaining product integrity.

Understanding the Importance of Standards in Steel Pipe Manufacturing

Adherence to industry standards ensures that steel pipes meet required mechanical properties and corrosion resistance. Compliance guarantees high-quality pipes with consistent diameter and wall thickness.

This is fundamental for reliability and performance, as standards dictate manufacturing processes and specifications. Understanding the importance of standards in steel pipe manufacturing is crucial for product integrity and end-of-the-process performance.

Key Considerations When Choosing Steel Pipes

Understanding the intended application’s mechanical properties is essential. The performance of steel pipes is impacted by different specifications like diameter and wall thickness. Corrosion resistance in harsh environments is a crucial factor.

The selection process is critical as various types cater to specific industry needs. The durability of steel pipes is greatly influenced by welding seam quality and manufacturing process.

Factors to Consider When Choosing Steel Pipes

Factors such as the intended end-use, environmental conditions, and budget play a crucial role in the selection process of steel pipes. It’s essential to consider steel pipes with the right alloy and thickness to withstand pressure and temperature variations.

Additionally, evaluating coating options for enhanced longevity and understanding the impact of drilling and flux on steel pipes are vital in making informed choices. Furthermore, assessing the specifications of steel pipes, including compliance with ASTM standards, ensures quality and reliability.

Understanding the Role of Steel Pipe in Infrastructure Development

Steel pipes, indispensable in civil engineering, provide strength and stability to infrastructure projects. Efficient distribution of utilities in urban and rural areas is facilitated by the versatile steel pipes. Their use minimizes maintenance, ensuring long-term cost-effectiveness.

Additionally, steel pipes play a pivotal role in developing sustainable and resilient infrastructure systems, contributing to the end of the process. The importance of steel pipes in infrastructure development cannot be overstated, making them an essential component in construction and development.

How has the Evolution of Steel Pipe Technology Influenced Modern Infrastructure?

Advancements in steel pipe manufacturing have led to highly durable and efficient pipes, with improved corrosion resistance through innovative coating technologies. Evolution in welding processes has ensured better seam quality and structural integrity. Modern steel pipes meet stringent industry standards for superior performance, while the use of spiral welded pipes offers enhanced strength and flexibility in pipeline construction.

Frequently Asked Questions

What are the advantages of using steel pipe in construction projects?

Steel pipe offers numerous advantages in construction projects. Its durability and resistance to wear and tear make it ideal for long-lasting structures. Additionally, steel pipe’s ability to withstand extreme temperatures makes it suitable for use in harsh environments.

Moreover, its lightweight nature reduces transportation costs, making it an economical choice. Lastly, steel pipe’s versatility allows for various applications, including water supply, gas distribution, and structural support.

How does the thickness and diameter of the steel pipe affect its strength and durability?

The strength and durability of a steel pipe are influenced by its thickness and diameter. Thicker pipes tend to be stronger and more durable than thinner ones, while a larger diameter allows the pipe to withstand greater pressure.

Choosing the right thickness and diameter depends on factors like intended use and environmental conditions.

Are there any special considerations to keep in mind when working with steel pipe, such as safety precautions or maintenance requirements?

When working with steel pipe, it is important to take some special considerations into account. Wear appropriate safety gear like gloves and eye protection, as steel pipe can be heavy and sharp.

Use proper lifting equipment or techniques to avoid injury. Regular maintenance involves inspecting for corrosion, leaks, and cracks. Ensure correct installation with proper support structures to prevent damage or failure.

Can steel pipe be used in a variety of applications beyond construction?

Steel pipe is a versatile material that finds applications beyond construction. It is widely used in the oil and gas industry for fluid and gas transportation.

Additionally, steel pipe plays a crucial role in manufacturing processes like automotive manufacturing and shipbuilding. It is even utilized in infrastructure projects such as water supply systems and sewage treatment plants.

Conclusion

In conclusion, steel pipes are a versatile and essential component of modern infrastructure development. From water supply systems to oil and gas pipelines, steel pipes offer strength, durability, and reliability. Understanding the basics of steel pipe, including its various types and manufacturing processes, is crucial in selecting the right pipe for your project.

Additionally, considering factors such as standards and design parameters ensures that the chosen steel pipe meets industry requirements. As technology continues to advance, steel pipe technology evolves as well, contributing to the development of more efficient and sustainable infrastructure. By unlocking the power of steel pipe, we can build a stronger and more resilient future for our communities.