Steel Plate Applications : The Ultimate Guide

Steel plate are one of the most versatile building materials and are used extensively in various industries, including construction, automobile, aerospace, and shipbuilding. They are known for their durability, strength, and resistance to wear and tear. In this comprehensive guide, we will delve into everything you need to know about steel plates.

From understanding what they are and how they are manufactured to the different types of steel plates available in the market. We will also compare steel plates with other forms of steel and explore their practical applications across various industries.

Lastly, we will look at the current market trends in steel plate usage and how the growing demand for these plates is affecting the steel industry. Read on to learn more about this essential building material that has revolutionized several sectors of our economy, including its length or width.

Table of Content

- 1 Understanding Steel Plates

- 2 Different Types of Steel Plates

- 3 Comparing Other Forms of Steel with Steel Plates

- 4 Practical Applications of Steel Plates

- 5 Market Trends in Steel Plate Usage

- 6 Frequently Asked Questions

- 6.1 What are the most common industries that use steel plates?

- 6.2 What factors should be considered when selecting a steel plate for a specific application?

- 6.3 What are some common types of steel plates and their properties?

- 6.4 How can the lifespan of a steel plate be extended through proper maintenance?

- 7 Conclusion

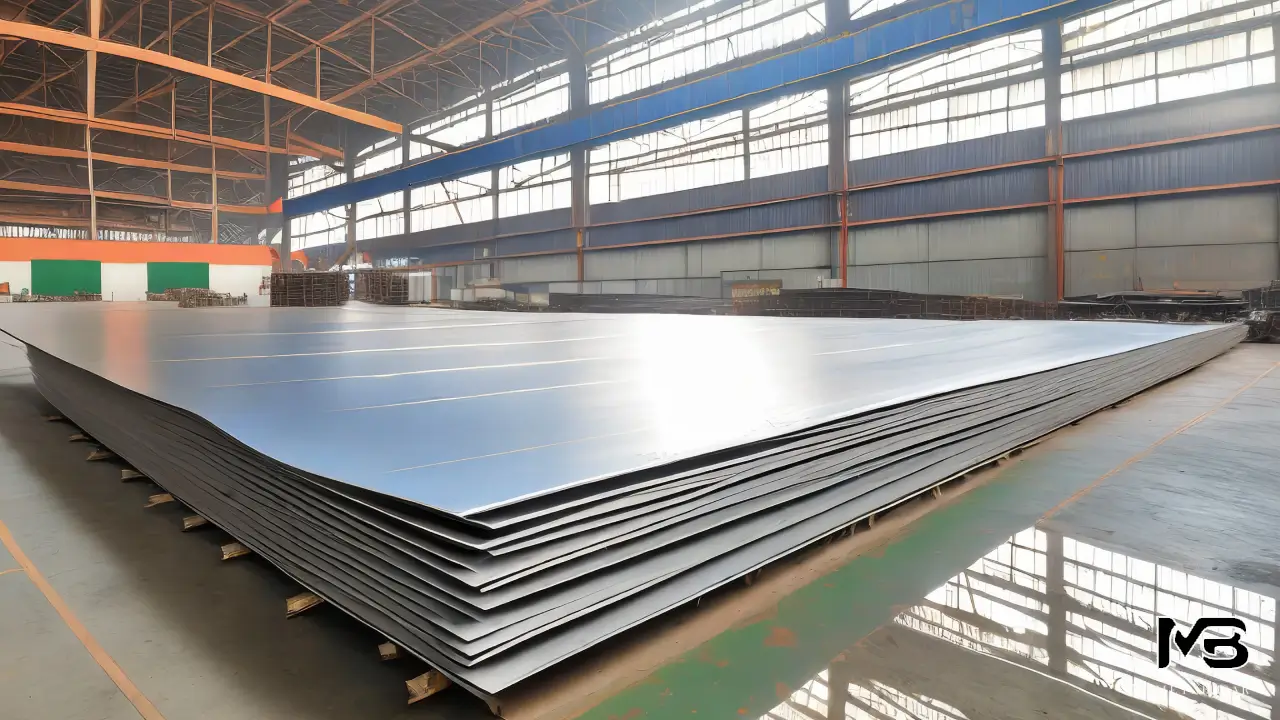

Understanding Steel Plates

Steel plates, widely utilized in construction and industry, boast durability, strength, and versatility. Often found in heavy equipment, ships, and bridges, they come in various sizes, shapes, and thicknesses. Understanding steel plates entails knowledge of their composition, properties, and applications, making them a critical component in various industries.

Definition and Basic Concept

The fundamental principle behind steel plates lies in their capacity to provide structural support and strength, making them vital in infrastructure, automotive, and machinery fabrication. These metal sheets, with a thickness exceeding 6mm, are indispensable in constructing buildings, bridges, and storage tanks. Understanding their definition is crucial for effective utilization.

The Manufacturing Process

The process of creating steel plates involves complex procedures like cutting, rolling, and precise temperature control for shaping. These plates may also undergo surface treatments to enhance specific properties for diverse applications. Understanding this manufacturing process provides crucial insights into the quality and characteristics of steel plates.

Different Types of Steel Plates

Steel plate variants, including carbon, alloy, and stainless steel, possess unique properties like corrosion resistance and strength. Categorizing plates by composition and performance is crucial for industry-specific applications. Each type serves distinct purposes in construction, manufacturing, and infrastructure. Understanding these variations is essential for material selection.

Carbon Steel Plates

Carbon steel plates are highly sought after for their strength and formability in various structural applications. With carbon as the primary alloying element, they exhibit exceptional hardness and strength. The versatility of these plates makes them suitable for a wide range of industrial and commercial uses. The manufacturing process involves controlled cooling and annealing for desired properties. Understanding these properties is crucial for effective material selection.

Alloy Steel Plates

Alloy steel plates are designed for high-temperature, pressure, and corrosive environments. Additional alloying elements enhance their mechanical properties, offering tailored compositions for specific industrial needs. From aerospace to energy sectors, they provide critical solutions. Understanding their unique characteristics is essential for optimized material selection.

Stainless Steel Plates

Stainless steel plates, known for their corrosion resistance and hygienic properties, are widely used in food processing and medical equipment. Their diverse grades and finishes, from brushed to mirrored, cater to different design requirements. The precise alloy composition and heat treatment involved in manufacturing ensure enhanced performance and durability.

Comparing Other Forms of Steel with Steel Plates

Steel bars and steel plates each serve different functions; bars are used for structural support, while plates offer larger surface areas for load-bearing. Conversely, steel sheets are thinner and more flexible, suitable for specific applications. Comparing these steel forms involves evaluating structural integrity, weight-bearing capacity, and fabrication requirements.

Steel Bars vs Steel Plates

When comparing steel bars to steel plates, it’s important to note that steel bars are often used for reinforcing concrete structures, providing tensile strength and stability. Conversely, steel plates offer broader load-bearing capabilities, making them suitable for heavy-duty applications.

The manufacturing processes for these two materials involve distinct shaping and finishing techniques. Understanding these differences is crucial for effective structural design and construction.

Steel Sheets vs Steel Plates

Steel sheets, being thinner and more flexible than steel plates, are suitable for bendable applications. Conversely, steel plates offer superior load-bearing capacity and structural support due to their greater thickness. The manufacturing processes for steel sheets and plates involve rolling, cutting, and forming to achieve desired dimensions and surface characteristics.

Steel Rolls vs Steel Plates

Steel rolls, formed through continuous casting, cater to large-scale industrial needs. Conversely, steel plates, produced by rolling molten steel between heavy rollers, find extensive use across manufacturing sectors. Precision cutting and shaping during production make steel plates versatile for various applications.

Steel Slabs vs Steel Plates

While steel slabs are the initial stage of steel plate production, steel plates offer versatility in design and application. Steel slabs are thick, flat steel structures, whereas steel plates, thinner and custom-cut, are ready for specific applications. Unlike steel plates, steel slabs require further processing before use.

Practical Applications of Steel Plates

Steel plates find extensive use in the construction of bridges and structural buildings, providing strength and resilience. They are also essential components in the automotive industry, offering durability and reliability.

Furthermore, steel plates play a crucial role in ship construction, ensuring overall strength and longevity. Additionally, the aerospace industry relies on steel plates for their high strength-to-weight ratio, while home appliances benefit from their durability and corrosion resistance.

In Construction Industry

Steel plates play a vital role in the construction sector, contributing to the stability of high-rise buildings, infrastructure, and bridges. They are utilized in the manufacturing of steel beams, girders, and columns, offering exceptional load-bearing capabilities. These plates provide essential support, ensuring the durability and resilience of construction projects.

In Automobile Industry

Enhancing vehicle chassis strength, steel plates are imperative in the automobile industry. They contribute to impact resistance, lightweight design, and fuel efficiency while ensuring the durability of automotive components. Crucial in manufacturing body panels and frames, steel plates play a vital role in ensuring the safety and longevity of automobiles.

In Shipbuilding

In shipbuilding, steel plates contribute to the structural integrity and seaworthiness of vessels, used in constructing hulls, bulkheads, decks, and internal partitions. Offering superior corrosion resistance, they play a pivotal role in creating reliable and seaworthy ships, crucial for marine applications.

In Aerospace Industry

The aerospace industry extensively utilizes steel plates for manufacturing aircraft structural components, including landing gear, wings, and fuselage, due to their strength, stiffness, and fatigue resistance. These plates play a crucial role in enhancing the overall performance and safety of aircraft, catering to the industry’s need for exceptional mechanical properties.

In Home Appliances

Steel plates find extensive use in the production of robust kitchen appliances such as stoves and ovens, as well as in the manufacturing of stainless steel sinks and countertops. The home appliance industry greatly benefits from the corrosion resistance of steel plates, ensuring the longevity and aesthetic appeal of household products.

Market Trends in Steel Plate Usage

Demand for steel plates is fueled by construction and infrastructure sectors. The automotive industry’s focus on lightweight, robust materials drives increased steel plate usage. Growing maritime trade and shipbuilding activities have also boosted consumption, alongside technological advancements in the aerospace industry. The rising demand for stainless steel plates reflects their increasing applications across diverse industries.

Current Scenario

With infrastructure development driving steady growth, the steel plate market is thriving. Technological advancements have improved material quality, leading to expanded product portfolios by global manufacturers. The current scenario portrays a growing preference for steel plates across various industrial applications, with market trends indicating a positive outlook for usage in multiple sectors.

How is the growing demand for steel plates affecting the steel industry?

The increasing demand for steel plates is driving growth in the steel industry. This trend is influencing production, supply chains, and investment decisions. Additionally, the need for steel plates is prompting technological advancements in steel manufacturing processes.

Frequently Asked Questions

What are the most common industries that use steel plates?

Steel plates are widely utilized in various industries, including construction, transportation, and manufacturing. Construction companies rely on steel plates for building bridges and skyscrapers.

The transportation sector uses them for ships, trains, and trucks due to their strength. Manufacturers employ steel plates for machinery and equipment requiring durability.

What factors should be considered when selecting a steel plate for a specific application?

When selecting a steel plate for a specific application, several factors should be considered. These include the intended use of the plate, its thickness and size, the grade and type of steel, and cost and availability.

Considering these factors will ensure that the selected plate meets the requirements of the application.

What are some common types of steel plates and their properties?

Common types of steel plates include carbon steel, alloy steel, and stainless steel. Carbon steel plates are strong and durable but susceptible to corrosion.

Alloy steel plates have added elements to enhance strength and durability. Stainless steel plates are highly resistant to corrosion and staining due to the addition of chromium and other elements.

How can the lifespan of a steel plate be extended through proper maintenance?

To extend the lifespan of a steel plate, regular cleaning to remove dirt and debris is essential. Applying a protective coating or paint can prevent corrosion. Inspecting for wear or damage and making timely repairs is crucial.

Lastly, storing the plate in a dry and covered area protects it from weather conditions.

Conclusion

To sum it up, steel plates have a wide range of applications across various industries due to their strength, durability, and versatility. From construction and automobile to shipbuilding, aerospace, and home appliances, steel plates play a crucial role in ensuring the safety and efficiency of different components and structures.

As the demand for steel plates continues to grow, the steel industry is witnessing significant growth and advancements. It is important to stay updated with the latest market trends and technologies to make informed decisions and leverage the benefits of steel plates in your specific application. So, whether you are involved in the construction industry or the aerospace sector, understanding the different types and applications of steel plates is essential for success.